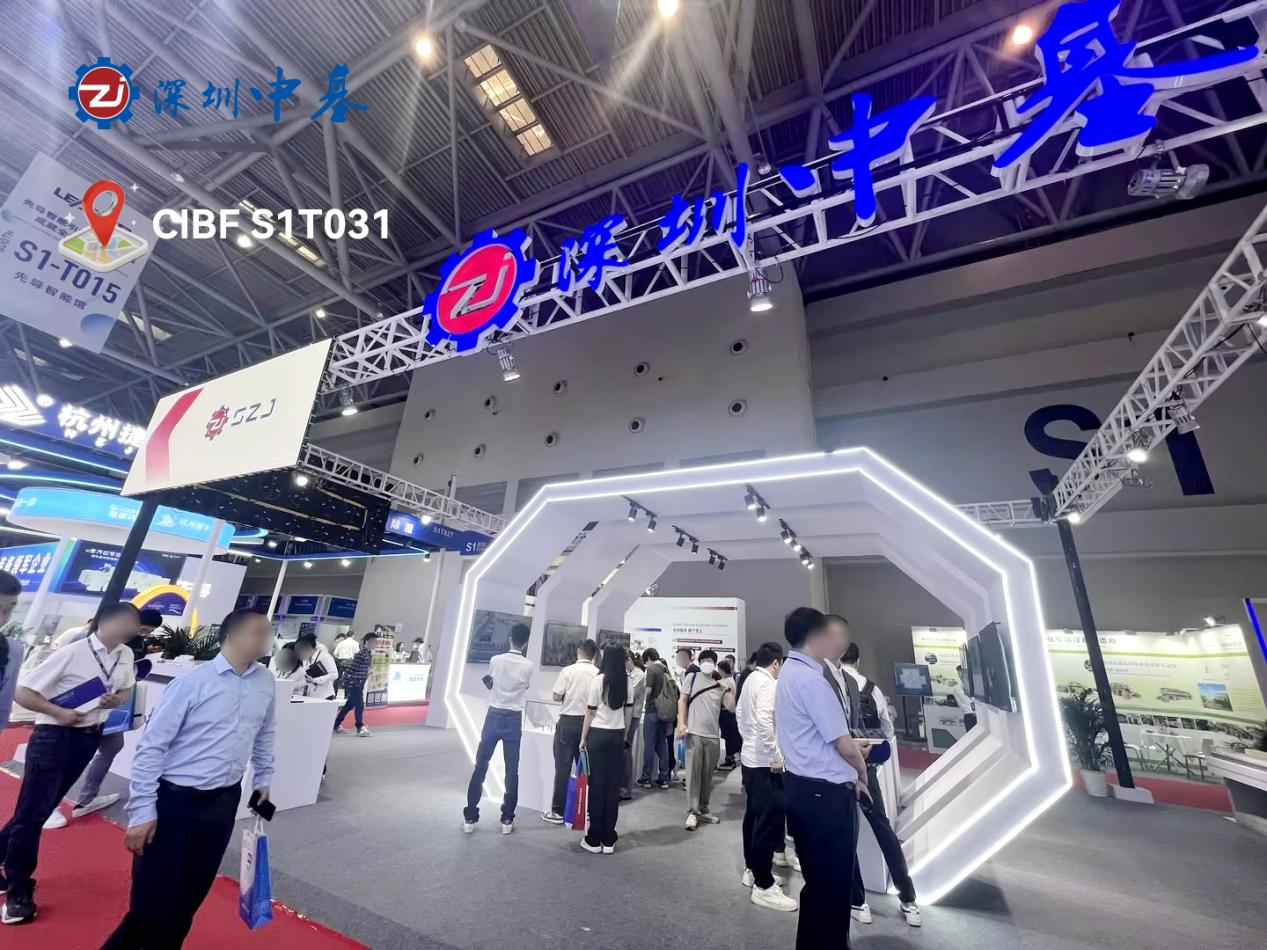

SZJ Makes a Splash at CIBF 2024

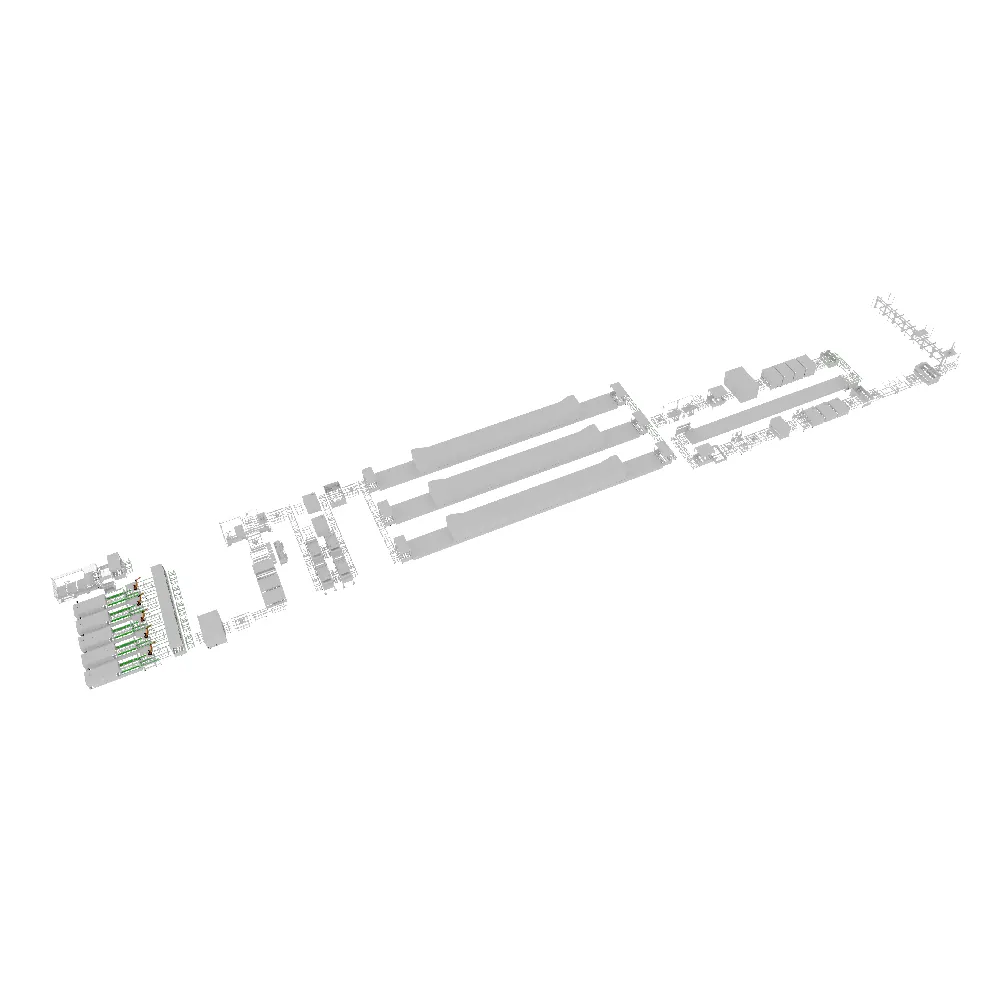

The 16th China International Battery Technology Exhibition (CIBF2024), held from April 27th to 29th, 2024, at the Chongqing International Expo Center, attracted great attention. As a leading enterprise in the field of intelligent manufacturing of battery equipment, SZJ showcased its intelligent production line model, demonstrating the strong capabilities and outstanding innovation